TerraTech Mechatronics are the durable approach to zero emision with electric products designed by experts in leading-edge motion control technologies with global resources to design, test, and manufacture complex products to deliver the solution you need now.

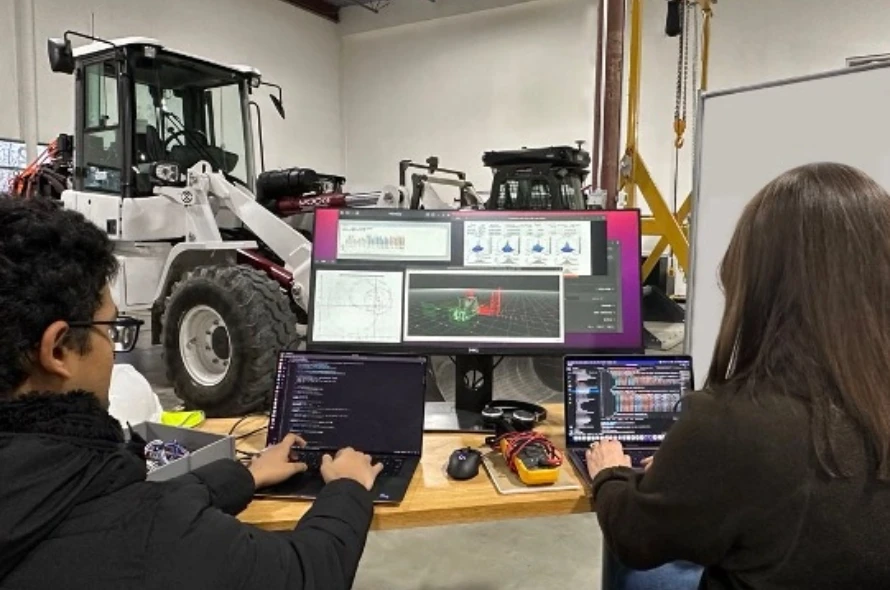

Integrated Electrification Technology System Approach

To get to market quicker with the latest electric technology, you need to ensure that all products connect seamlessly and have the support you need from the concept stage to production to service after-sales. Moog offers a comprehensive set of hardware + Software + Digital connectivity combined with application engineering capabilities to produce turnkey systems with safety, performance, and productivity. Are you ready to quickly control, create and digitally connect your next-generation machine and job site?

TerraTech – giving you the ability to transition all your machine to zero emission. Today.

High Voltage DC Power

CAN Connections

Analog & Digital I/O

Low Voltage Output

Ethernet Port

Coolant Port

Coolant Port

EVCM

Electric Vehicle Control Module (EVCM)

Motion Control & Power Management System

Moog’s state-of-the-art controller is often considered the intelligence of the integrated system, with Codesys-based PLC functionality and the ability to connect and control numerous hardware devices seamlessly. Moog EMCM has an open architecture (CAN J1939) and advanced data collection capabilities, enabling you to add devices easily and gain valuable machine data. Designed to be rugged to handle shock vibration and extreme ambient temperatures, the EMCM is a high performance, configurable and simple to use. Best of all, it is highly scalable to so you can easily integrate third-party sensors and other devices (i.e., IMU, Cameras, HMI) to help you configure your machine as needed for your customers.

Advantages

Reduce your risk and costs with a development environment that is easily customizable across all your machine so you can build in your differentiation

Enable machine optimization, safety, and data collection for continual improvements that get you ready for your next level of automation and digitalization

Trusted by OEMs in many human-rated applications worldwide for long service life, and reliability in some of the world’s most challenging applications

Please provide your information to access the technical brochure.

Motor

Internal Brake

Gearbox

3 Phase Power Connectors

Coolant Ports

Traction Drive Assembly

Traction Drive Assembly

Moog has sophisticated motor design and manufacturing capabilities that ensure rugged performance and flexibility integrating into your overall system. It is compact, lightweight, and efficient with the impressive power density and optimized package size. With designs for traction and power train applications, high torque and load capacity, and special lifetime seals.

Advantages

Interconnect hardware product easy to integrate into the electrification system reduces development, validation, and verification time

Speed and torque profile to match and replace existing hydraulic traction motors

Tunable to give you the right acceleration and deceleration profiles to match your operations

Please provide your information to access the technical brochure.

Stator

Rotor Shaft

3 Phase Power Connection

Coolant Ports

Drive Train Motor

Drive Train Motor

Electric motor and Final Drive assembly for wheeled vehicles.

Advantages

Ability to modify standard series to meet performance requirements

Increased productivity and improved cycle times

Improved product quality through accurate control

Please provide your information to access the technical brochure.

Spherical Rod End

Motor

Power and signal connectors

Gearbox

Ball screw

Nut

Rod

Electrical Cylinder

Electric Cylinder

Powerful, easily configurable, and efficient electric motion hardware

Our Electric Linear Cylinders, also known as Electro-Mechanical Actuators (EMA), are the workhorse hardware required for powerful yet efficient actuation for all-electric construction systems. Our product is trusted for its long-lasting performance and configurable options to help you optimize your machine. Our in-house design and manufacturing capabilities make it easy to integrate this robust technology with power electronics and controls to help you build your differentiation into your machine.

Advantages

High force performance with peak forces well over 130kN, specifically designed and manufactured to meet the current performance demands (force/Speed) of hydraulic cylinders for lift, tilt, boom, and stick

Trusted by OEM’s worldwide as the performance leader you can count on to meet performance specs

Proven hardware that is ready for quick integration, test and validation, and production

Please provide your information to access the technical brochure.

High DC Voltage

12V Output

24V Output (On Back)

Signal Connection

Coolant Port

Coolant Port

Auxiliary Power Module

Provides 24V or 12V power to auxiliary functions on the machine, such as lights, fans, joysticks, etc.

Advantages

Auxiliary power supply provides additional 12V/24V power for auxiliary functions

Liquid cooling increases the life and longevity of the EVCM

Designed to comply with ISO 14990 standards for electrical safety, ISO 13849 for functional safety

Please provide your information to access the technical brochure.

Single Axis Servo Drive

Single Axis Servo Drive

Inverts high voltage DC power to 3 phase power for actuators or motors. Single axis is used for high power applications.

Advantages

Modular staking systems for easily fitting into any machine

Drive controls provide scalability across multiple machines saving development time and reducing manufacturing complexity

Field-replaceable modules ensure your machines are equipped for a long service life

Please provide your information to access the technical brochure.

Dual Axis Servo Drive

Dual Axis Servo Drive

Inverts high voltage DC power to 3 phase power for actuators or motors. Dual axis drive can provide power to two lower control axes for a compact solution.

Advantages

Modular staking systems for easily fitting into any machine

Drive controls provide scalability across multiple machines saving development time and reducing manufacturing complexity

Field-replaceable modules ensure your machines are equipped for a long service life

Please provide your information to access the technical brochure.

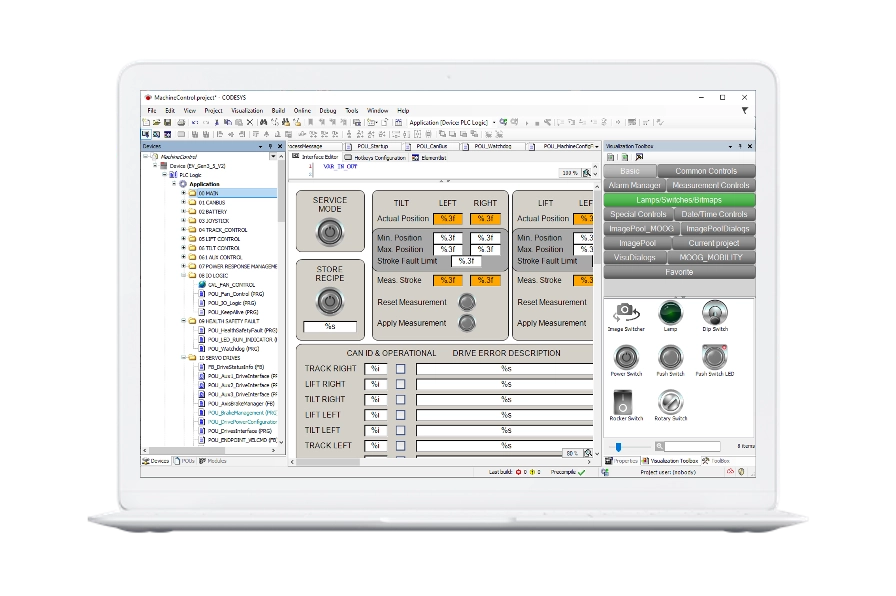

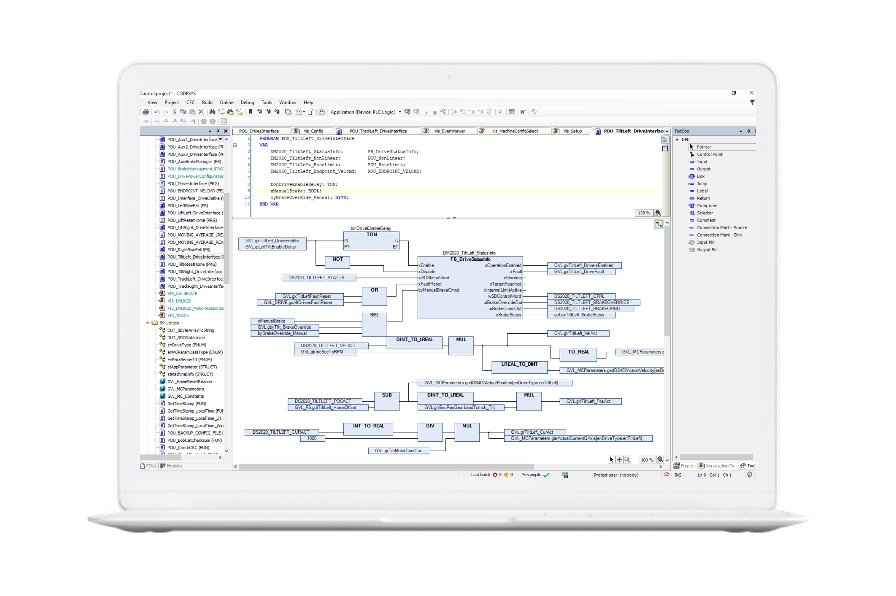

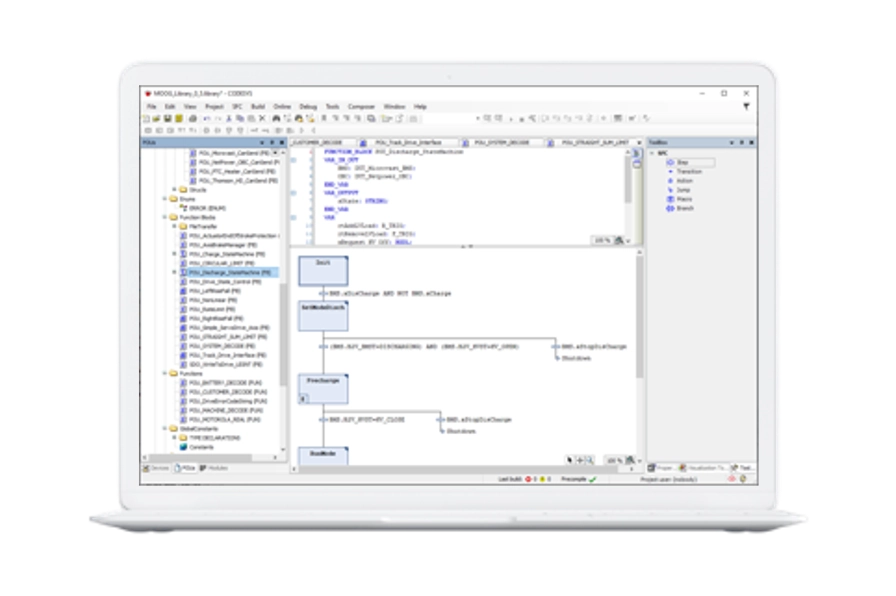

Software Development Environment

Software Support and Co-Creation of Application

Moog offers extensive application engineering and support and will consult OEM’s to support customer projects Moog has extensive experience and can support the entire system level software development. We help co-create programs that help differentiate and help meet the requirements of the construction and other off highway vehicles.

Advantages

Remote diagnostics enabled with interfaces to cloud database and onboard analytics for decision making

Built-in algorithms and a developer toolbox enable you to build in your machine differentiation with more software-enabled functionality for greater productivity and tool usage

Ready for digital connectivity, continuous learning, and your next level of automation

Please provide your information to access the technical brochure.

Software Development Kit

The software developer is free to mix-and-match between the available programming languages and choosing the type than best fits the task a hand. For the experienced programmer that is used to writing software in C-language.

Please provide your information to access the technical brochure.

Machine Monitoring Software

For advanced diagnostics it is possible to capture high resolution data. Event and Data logging available on machine or over the air through IoT for easy machine diagnostics.

Please provide your information to access the technical brochure.

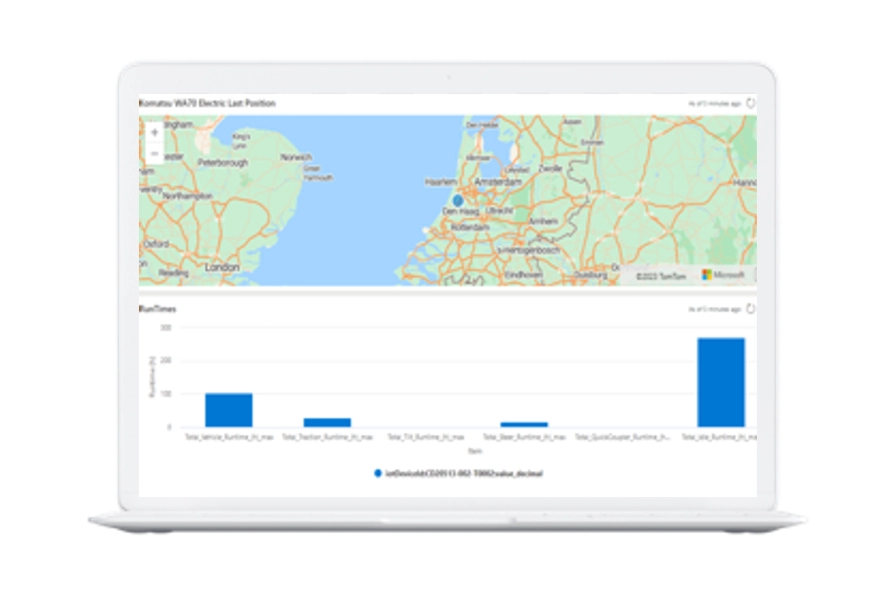

Digital Insights

Leading Vehicle Efficiency and Productivity Through Advanced Telematics

Moog’s integrated digital solutions provide advanced capabilities to help OEM’s, fleet owners, operators, and maintenance managers get the most of their vehicle or fleet. Our hardware and software solutions are developed with future capabilities in mind, providing the foundation of electronics, sensors and software to enable advanced driver assistance and automation features to be deployed to the machine or fleet as those features are deployed.

Please provide your information to access the technical brochure.

Partner with us for

greater sustainability,

productivity, and a digitally

connected future.