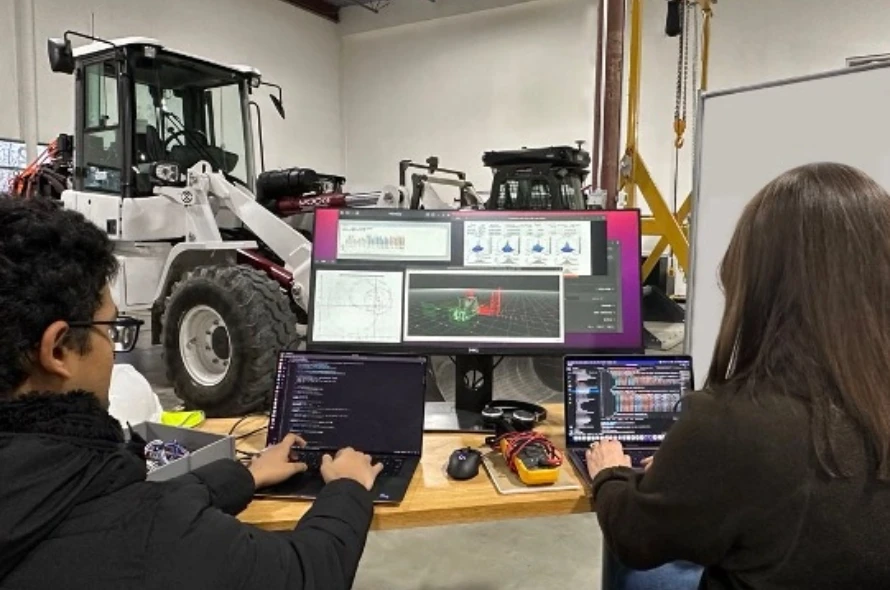

An integrated solution allowing a quicker journey to market, streamlined production, and simplified service.

Full electric motion system architecture

Scalable. Modular. Configurable.

An integrated solution allowing a quicker journey to market, streamlined production, and simplified service.